Products

GPK-3NC|TFG-200NCHS|TFG-200NCH|TFG-300NC|4-Axes CNC Deburring M/C|PRG-1NC

PRG-1NC FOUR|TPG-200NC・TPG-500NC|GP-300NC|Hypoid Gear Semi Topping M/C

Gear Chamfering M/C

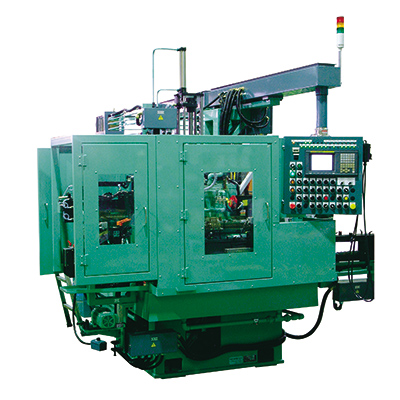

GPK-3NC

Gear Chamfering M/C

Various kinds of gear systems Chamfering at high speed cutting.

- Features

-

Easy setup and time reduction realized by NC.

1. Cutting process can avoid the rise of tooth face and make post-process tools easy.

2. Regrinding of rake face is only required so it contributes to an amazing long tool life and significant costs reduction.

3. Reduction of change-over time and part costs by NC.

4. Easy automation.

5. High speed machining by NC synchronization and special cam mechanism.

- Specifications

-

● Chamfering amount Max.C0.7 equivalent

● Work module 0.75~2.5

● Work tooth bottom diameter φ20.5~φ150

● Work tooth width 15~45 ※Applicable for parts with shaft

● Cutting speed MAX.0.5sec/tooth ※It varies with the workpiece mass

● NC device FANUC 35i (3 axis control)

- Special attachments

-

-

● Clamp jig

● Tool holder

● Tool

● Coolant device

● Automatic positioning device

● Automation device (loader, conveyor etc.)

TFG-200NCHS

2-Axes CNC Gear Deburring M/C

This machine performs rolling chamfering for processed gear end and at the same time, removes burrs and flashes of gear end face with roller cutter.

This machine is superior to cost performance, also it saves place.

- Features

-

This machine makes it possible to perform rolling and chamfering of tooth edge surfaces of acute angle side (simultaneous machining of obtuse angle side as well will be possible) for helical gears and spur gears.

1. It is operated by NC system. Cutting position stopper is not required.

2. Cutting position can be set freely.

3. Even if the width of teeth is different, parts change is unnecessary because deburring roller cutter opens and close with the air cylinder.

4. Work drive system.

5. This machine's features are horizontal design and attaching work piece to jig horizontally. These features make it possible to cope with conveyor transports and other automated lines easily. - Specifications

-

-

● Chamfering module 1.0~4M

● Cutter stroke MAX210mm

● The axis interval between work and cutter MIN90mm

● Outer dia. of frazing cutter φ140mm

● Outer dia. of deburring roller cutter φ120mm

● NC device FANUC 35iB

● Machine size W820mm*D2400mm*H2250mm

● Machine weight About 1650kg

● Option specifications Tail center device, Automation device

TFG-200NCH

2-Axes CNC Gear Deburring M/C

This machine performs rolling deburring for processed gear end and at the same time, removes burrs and flashes of gear end face with spring type roller cutter.

- Features

- 1. It is operated by NC system. Cutting position stopper is not required.

2. Cutting position can be set freely.

3. Even if the width of teeth is different, parts change is unnecessary because deburring roller cutter opens and close with the air cylinder.

4. Drive system, Cutter.

5. This machine makes it possible to perform deburring of tooth edge surfaces of acute angle side (simultaneous machining of obtuse angle side as well will be possible) for helical gears and spur gears. - Specifications

-

-

● Chamfering module 1.5~4M

● Cutter stroke MAX200mm

● NC unit FANUC 35iB

● Machine size W1200mm*D2300mm*H2250mm

● Machine weight about 3000kg

TFG-300NC

3-Axes NC Gear Chamfering M/C

This machine is auto loaded when work is set in V receiver. And then it performs rolling chamfering for acute angle gear end by program setting in advance.

At the same time, it removes burrs and flashes of gear end face with roller cutter.

- Features

-

This model's feature is the rolling chamfering of acute angle tooth end of multiple helical gear for shaft,etc.,with high efficiency.

1. Work drive system is adopted. Sensor can index gear automatically and engage the cutter smoothly.

2. This machine is equipped with NC system. Cutting depth position stopper is not required.

3. The station turret cutter can process four or six types of different dimension gears.

4. Cutting position is freely set.

5. Cutter change by work replacement is not required.

6. Even if the width of teeth is different, parts change is unnecessary because deburring roller cutter opens and closes with the air cylinder.

7. Jig of both centers can be processed only work too. - Specifications

-

-

● Chamfering module 1.5~4M

● Max.shaft length 400mm

● X-axis stroke 200mm

● Y-axis stroke 160mm

● Z-axis strike 350mm

● NC device FANUC 35iB

4-Axes CNC Deburring M/C

Gear Chamfering M/C

This machine is equipped with automatic teaching system.

So it can produce various and small amount of work easily.

It’s easy for any operators to control this machine.

- Features

- 1.The teaching system is equipped with the touch probe. It traces the machining part of work, thus positioning the work in high accuracy.

2.The machine can also bore and mill the work by changing the tool.

3.The automatic work loading and unloading units and stocker can be optionally provided to the machine. - Specifications

-

-

● Max machining dia. MAX.500mm

● Work thickness (height) MAX.300mm

● Work Gear: 1.5M~5M, Other:Corner R min 2

● NC axis(FANUC) X-axis:Cutter advance/retract 375 stroke 1.0kW

Z-axis:Cutter up/down 465 stroke 1.0kW

B-axis:Cutter swivel +45°~−45° 0.9kW

C-axis:Work index 0.9kW

● Cutter axis 0.4kW 10,000rpm.(inverter control)

● Machining time Per tooth:About 1 sec. (module 3)

● Machine size 1,900×950×2,120mm - Special attachments

-

-

● Work stocker

● power chuck

● special tools

● others

PRG-1NC

2-Axes CNC Gear R Chamfering M/C

This is the R chamfering machine for various gears. This machine is equipped with NC system. So it doesn’t have to replace cams, change gears etc. Displacement can be done easily and smoothly.

- Specifications

-

-

● C-axis Work index (Precision wheel drive. Dynamic pressure : METAL Bearing)

● Z-axis Cutter left/right slide (Large size BALL THREAD+support Bearing)

● Hydraulic Cutter advance/retract slide (Angular type slide unit)

● Maximum dia. of work gear(external tooth) 300mm

● Maximum dia. of work gear(inner tooth) 100mm

● Maximum dia. of work gear 30mm

● Maximum pitch of work gear 6M 4DP

● Cutter spindle

Spindle speed 1000min-1~10000min-1[5.5kw High-frequency MOTOR]

Lubrication CPS lubrication MC-D series [TACO]

Bearing All ceramic bearing

Axial end HSK A63 (Manual clamp type)

● Control unit FANUC 35iB

● Standard attachment

・Standard type Coolant tank

・Leveling Block

・Standard Tool Box - Special attachments

-

● Variety type Fixture A'ssy

● Tool & tooling, original tool presetter

● Semi-dry, Dry-cut system

● Loader & Unloader device

● Auto tooth positioning device (Mech. Type or Touch Probing type)

PRG-1NC FOUR

4-Axes CNC Gear R Chamfering M/C

- Specifications

-

-

● C-axis Work index (Precision wheel drive. Dynamic pressure : METAL Bearing)

● Z-axis Cutter left/right slide (Large size BALL THREAD+support Bearing)

● X-axis Cutter advance/retract slide (Angular type slide unit)

● Y-axis Cutter head swivel (BALL THREAD+Hyd. Power clamp)

● Cutter spindle

Spindle speed 1000min-1~10000min-1[5.5kw High-frequency MOTOR]

Lubrication CPS lubrication MC-D series [TACO]

Bearing All ceramic bearing

Axial end HSK A63 (Manual clamp type)

●Control unit FANUC 35iB

●Standard attachment

・Standard type Coolant tank

・Leveling Block

・Standard Tool Box - Special attachments

-

● Variety type Fixture A'ssy

● Tool & tooling, original tool presetter

● Semi-dry, Dry-cut system

● Loader & Unloader device

● Auto tooth positioning device (Mech. Type or Touch Probing type)

● Additional 1-axis (Cutter up/down slide, Work head tilt device)

● ATC device (When this device was attached, Cutter spindle type becomes MAS BT 40 type.)

TPG-200NC・TPG-500NC

Vertical 2-Axes Angle Chamfering・Vertical 5-Axes Corner Chanfering M/C

TPG-200NC/Vertical 2-Axes Angle Chamfering M/C

This machine is for angle chamfering of transmission clutch teeth (involte spline).

- Features

- 1. Due to vertical construction, the machine is suitable for space saving and line formation.

2. NC indexing system is adopted.

3. Cutter head against work head is moved up and down for chamfering operation.

4. Work head moves backward approx. 200mm after completion of processing. It makes easy to attach/detach.

5. For chucking of workpiece and driving work head, hydraulic force is used.

(Hydraulic tank unit is installed separately.) - Specifications

-

-

● Machined gear diametr 50~110mm

● Machined gear modules 1~3

● Machine teeth number 18~60

● Chamfering angle 90°~120°

● Electric motors

Up and down slide 1.8kW AC servo motor(With brake)

Cutter 1.5kW 4P

Hydraulic 0.75kW 4P

Coolant oil pump 400W 2P

Indexing AC servo Motor

● Machining time Max. 0.8sec./tooth

● Floor area 1,300×2,300

● Weight About 3,000kg - Special attachments

-

● 2-axes cutter head, Fixed and adjustable types

● cutter

● Fixture jig

● Outer teeth positioning device

TPG-500NC/Vertical 5-Axes Corner Chamfering M/C

This machine is for chamferring the corners of gear end face of inner tooth and outer tooth.

Though the conventional machine was hard to chamfer the unequal angle of gear simultaneously. This machine can chamfer the gear of unequal angle as well as the gear of equal angle in high accuracy.

- Features

- 1. The independent cutter spindle can chamfer the gear even if different angle. (Angle indicated by encoder.)

2. The cutter spindle is easily set with the linear gauge with digital indication.

3. NC control system can adjust the index of work, cutter position and infeed finely and easily. - Specifications

-

-

● Gear dia. 50~100mm

● Work module 1~3M

● Chamfering angle 90°~120°

● Motor:Cutter cross feed 1kW AC servo motor:2 units

Cutter vertical feed 1kW AC servo motor:2 units

Work index 1kW AC servo motor:1 unit

Cutter axis 0.75kW 4P 2 units

Hyd. pressure 1.5kW 4P

Coolant 0.4kW 2P

● Machining time MAX. 0.8 sec./tooth (Changed by chamfering angle, module)

● Floor area 1400mm×2500mm

● Weight About 3000kg

GP-300NC

5-Axes NC Hypoid Gear Chamfering M/C

This machine is the best match when gear chamfering process is acted in hypoid gear, bevel gear and internal gear.

- Features

- 1. High Quality Chamfering

This machine acts shaving cut by formed BITE and make it possible to make high quality chamfering form.

2. Low Cost Tool

The tool of this machine has wonderful life span and very reasonable cost. It doesn't revolute in high speed because edge of tool doesn't get damage by heating.

3. Saving resources & Saving energy

This machine is able to act semi-dry cutting and dry cutting.

So, saving oil, saving electric power and saving space.

4. Human safety conscious

By the following efficient units are attached, Work setting position and hight, Auto probing (of tooth positioning) by touch sensor〔*〕, Front auto door with Area sensor attached〔*〕, and Auto Work Ejecting device〔*〕etc..., we let the operator's working load light.

☆But,〔*〕marking device means optional device. - Specifications

-

-

● Max. machining dia. Max.φ300mm, hight 100mm (axle shaft is not include.)

● Max. machining module Max. M=6

● Cutting Speed 300tooth/min.

● Control unit FANUC 0iM

● Standard attachment

Standard type Coolant tank, Leveling block, Standard tool box - Special attachments

-

● Variety type Fixture A'ssy

● Formed BITE

● Cutter Arbor

● Auto tooth positioning device (Auto work type detection system etc...)

● Loader & Unloader device

● Tail stock device

● Tail stock power slide device

● Work contact confirmation device

● Front auto door & Area sensor

● Dry-cut or Semi dry-cut spec.

Hypoid Gear Semi Topping M/C

Hypoid Gear Semi Topping M/C

Original grind

- Features

- 1. Chamfering processes a hypoid gear ridgeline by grinding it after heat-treatment.

2. Whetstone life is improved by an original method to grind.

3. A normal whetstone to CBN whetstone enable to use by high rigidity and high-speed turn spindle.

(The number of revolutions is adjusted by inverter.)

4. It is possible to correspond to wide-ranging work by five axes CNC and controlling three axes simultaneously.

5. A rotary dress device is attatched to whetstones generally.

6. In a dresser, the processing shape is stably maintained by automatic revision.

7. Wet type grinding method prevents from being burnt.

8. It equipped with eco-friendly front cover and mist collector. - Specifications

-

-

● Process range DRIVE PINION dia :φ50~φ100 length : MAX350mm

DRIVEN GEAR dia :φ100~φ200 length : MAX50mm

(It corresponds by a special specification excluding this range.)

● Chamfering amount MAX1mm (process width)

● Chamfering angle 30゜~45゜

● Adjustment of spindle angle by automatic(CNC)

● Spindle ADV/RET 200mm(CNC)

● Spindle UP/DOWN 200mm(CNC)

● Spindle R/L 100mm(CNC)

● Pitch of process 0~10m/min (Three axes simultaneous control)

● Over ride 10m/min

● Motor of spindle 1.5kW 2P MAX10000rpm (control by inverter) - Special attachments

-

● An automatic positioning device by a touch probe

● Setting JIG A'ssy.

● Ejector unit

● Dressing tool