Products

NC Six-Surface Milling M/C|SFV-300NC

Others

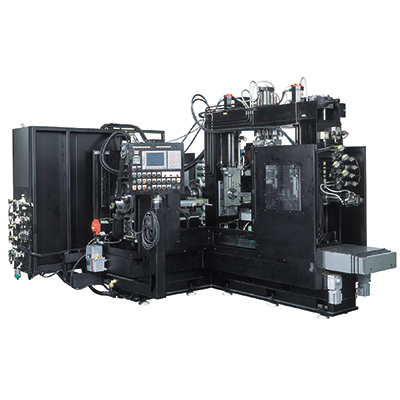

NC Six-Surface Milling M/C

NC Six-Surface Milling M/C

In addition to the automatic work setting device which automatically turns work in horizontal and vertical,

the special original jig attached to right and left main shafts enables high-speed and high-accuracy machining.

- Features

- 1.Full automatic processing of six-surface which was impossible in the past became possible.

2.The area of the datum level of the workset is automatically switchable to 2 type, thin and thick.

3.Saves time to change jigs depending on the machined surface. It shortens processing time and reduces cost.

4.Synchronous machining of the left and right spindle improves accuracy of the machined surface. - Specifications

-

-

● Machining size(MIN) 25×50×50㎜

● Material(work size) 200×200×300㎜

● Cutter diameter MAX250㎜

● Cutting speed 100~1200㎜/min

● Fast traverse 10,000㎜/min

● Main axis rotation number 150~550rpm

● Shape of main axis end face Cutter direct attachment

● Main axis motor AC spindle motor(11KW)

● X axis feed motor AC servo motor(7KW)

● Y axis feed motor AC servo motor(3KW)

● Z axis feed motor AC servo motor(3KW)

● AB axis feed motor AC servo motor(1.6KW×2)

● Hydraulic motor 3.7KW 4P

● Lubricant motor 25W 4P

● NC device FANUC 31 iB

● Operation panel 8.4inch(color)

● Weight 12,000㎏

● Power 50kVA

● Air consumption500Nℓ/min(5.5kW) - Special attachments

-

-

● Screw chip conveyor

● Up & Down jig for work clamp

● φ250 cutter(right and left free type)

● Stocker

● Corresponding to robot

● Material measuring device

● Material brush device

● QR code reading device

SFV-300NC

3-Axes NC Centering M/C(Vertical)

The height of the workpiece is designed low and the workpiece comes to the front, so that the operator can install and remove the workpiece less stressfully.

There is no construction below the workpiece, and no chip will be accumulated.

The interior coolant flow is so smooth that it also is less stressful for the operator to clean the machine.

The exchange of the Combination tool is quick since the tool clump type is HSK-A63.

The cutter spindle is on the near side and even heavy tool can be easily replaced.

The Combination tool is in-house design and manufacture, therefore we offer this device with reasonable price.

The center drill is center-through-coolant specification. This features a long life and improved surface roughness of the center hole.

- Features

- All jigs are designed and manufactured in-house.

Two kinds of the standard jigs can be offered.

Self-centering 1 vice type with single hydraulic motor.Self-centering 2 vice type with double hydraulic motor.

During clamping, Stable high-precision machining is achieved by self-locking by the trapezoidal screw.

In addition, simultaneous machining by the left and right spindles cancel out the thrust in the axial direction.This enables more effective and higher-precision machining.

Double row cylindrical rollers are arranged in the front and rear parts on the spindle, and angular bearings are arranged in the opposite direction.This exerts stronger radial rigidity and therefore a combination tool of large diameter face mill type is installable. - Specifications

-

-

● Spindle Motor 2-2kW4P with Inverter (Fuji Electric)

● Spindle Speed 600-i ~190-i

● Spindle Nose HSK-A63, Manual clamp type

● Coolant to Center Drill and Combination Tool Spindle through, Rotary joint maker : Deublin

● Safety Cover Full-coverage

● Front Auto Door Air cylinder type (with open/close end confirmation proximity SW)

● Work Pushing Device Mounted on either left or right side of the cutter spindle slide, Pressed by spring + NC axis (with confirmation proximity SW)

● NC Axis Jig vertical slide (with brake), Cutter spindle slide (Left), Cutter spindle slide (Right)

● NC device FANUC 0i-MF

● Coolant Tank Water-soluble Tank capacity : 200ℓ

● Disposal of chips, etc. Dedicated large diameter magnet screw conveyor, with Disc type oil skimmer - Special attachments

-

-

● Dedicated Combination Tool

● Dedicated Jig

● Work Delivery Device

● Work Rest

● Dedicated Tool Presetter

● Cases when a lot of chips are discharged Magnetic roller conveyer , is available (7 steps or 8 steps)

● Others One hand motive SW, Area sensor, etc.