Products

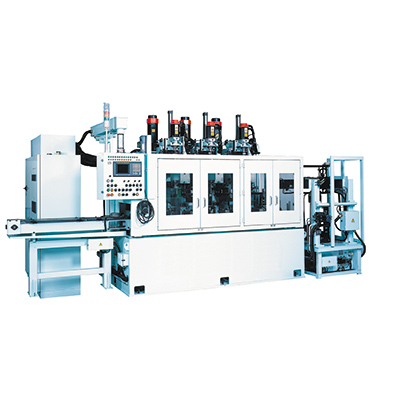

End Face Trim・Oil Hole Molding M/C|4MP-3H

Trim

End Face Trim・Oil Hole Molding M/C

This machine can trim the end face (finish cut) of transmission parts (clutch hub,drum,etc.) and pierce (oil hole) at a high speed and in a short time.

A fully automated and unmanned operation becomes possible when the transfer unit and the auto locating device for a works are provided on this machine.

- Features

- 1.The secondary burr that occurred in drilling does not occur.

2.The tool service life is prolonged and it is easy to maintain the tool since the work is processed with the punch & die.

3.It is easy to dispose of chips and swarf since they are discharged in some lamps.

4.An environment in plant is well maintained since the coolant system is not required.

5.The hole position is easily adjusted. And also, a set-up is easily changed by only program since the index and the vertical movement of jig are controlled with the servo motor.

6.About the different hole diameter sizes, the machine is equipped with the automatic pierce changer, thus eliminating a set-up change. - Specifications

-

-

● Cycle time Punching time of 1 hole : within 1.1 sec. (including indexing time)

● NC device FANUC 35iB, For work rotary index, For jig (work) up/down movement (special attachments)

● Driving source Pneumatic・hydraulic pressure, Hydraulic pressure 14MPa, Pneumatic pressure 0.35MPa - Special attachments

-

-

● Burr detector after piercing

● Auto transfer system

● Auto workpiece locating device

● Chip conveyor

● Piercing type punch & die

● Trim type punch & die

● Vertical locating NC unit

● Auto piercing changer

4MP-3H

4-Axes CNC End Face Trim, Piercing, Ditch Molding M/C

This machine can trim the end face (finish cut)

It is a device that gives the processing of the trim on the edge side (a finish cut of an end face), the Pierce hole opening (processing of an oil hole), and the snap ring ditch molding to the transmission parts (a clutch hub, a drum etc...)

A super-high-speed processing was achieved because the processing that had been done by the oil pressure drive was changed to the mechanical drive that used the SERVO MOTOR so far.

It is high-speed and driving in all automatic uninhabited is possible by the combination of the cam type transportation device with the stocker device.

- Features

- 1.The secondary burr that occurred in drilling does not occur.

2.The tool service life is prolonged and it is easy to maintain the tool since the work is processed with the punch & die.

3.It is easy to dispose of chips and swarf since they are discharged in some lamps.

4.An environment in plant is well maintained since the coolant system is not required.

5.The hole position is easily adjusted. And also, a set-up is easily changed by only program since the index and the vertical movement of jig are controlled with the servo motor. - Specifications

-

-

● Machining time Piercing time of 1 hole 0.35 sec. (Including indexing time)

● NC device FANUC 35iB

For WORK index, For press slide driving, For press slide exchange driving, For JIG slide (up/down)

● Driving source Pneumatic・hydraulic pressure, Hydraulic pressure 3.5Mpa, Pneumatic pressure 0.35Mpa - Special attachments

-

-

● Burr detector after piercing

● Auto transfer system

● Auto workpiece locating device

● Chip conveyor

● Piercing type punch & die

● Trim type punch & die