Products

Rack Rolling Machine

VRF 1000S

Vertical Rack Rolling M/C

There is OPD auto-adjustment mechanism by two sets of CNC in a TOOL HOLDER,

and adjustment of diameter 4mm is possible.

- Features

- This machine is a rolling machine with the flat dies.

The rolling of various outer diameter screws and the spline is performed. This machine has high efficiency and high precise.

In addition, there is OPD auto-adjustment mechanism by two sets of CNC in a TOOL HOLDER, and adjustment of diameter 4mm is possible.

Independent positioning for the main slide is possible by CNC. So this machine can process with the same tool is if there is it between even number teeth or odd number teeth, as for less than diameter difference 4mm of the same specifications. - Specifications

-

-

● Rolling thrust 3500kg

● Outer diameter of rolling point MAXφ50mm

● Length of WORK MAX500mm

● Width of rolling point (at the time of processing 1M ) MAX150mm

● Module MAX1.5M

● Rolling tool(The size that installation is possible) MAX930×250mm

● Slide stroke 1200mm

● Rack drive servo motor α40i×2

※The independent adjustment of the tool position of R, L is possible.

● Center drive servo motor α8i×2

※The round trip rolling that the free degree is high is possible.

● Servo motor for OPD adjustment α4i×2×2

※The installation of two sets of tools is possible and can adjust it separately.

● M/C weight 12000kg - Special attachments

-

-

● Tool

● COOLANT unit

● JIB CRANE

● Both center

● Tool spacer

● Auto transfer system

VRF-600

Vertical Rack Rolling M/C

It is possible to perform rolling processing with high efficiency and high accuracy

by 4-axes CNC and independent slide control.

- Features

- This machine is a rolling machine with a flat dies.

The rolling of various outer diameter spline and screws is possible with high efficiency and high accuracy.

This is vertical rolling machine.

The feature of the machine is a slide control by an independent servo motor.

It is very easy to set the tool.

The machine is equipped with cooling device of ball screw and it prevents the deterioration of the accuracy by changes in temperature. - Specifications

-

-

● Rolling thrust 3500kg

● Outer diameter of rolling point MAXΦ50mm

● Length of the work MAX300mm

● Width of rolling point (Depends on the module) MAX150mm

● Module MAX1.25M

● Rolling tool MAX720×100mm

● Slide stroke(all stroke) 1000mm

● Max. fast forwarding speed 20m/min

● Drive servo motor α40B/3000i×2

● Machine weight 7000

● Machine Size L3000*W2000*H3150 - Special attachments

-

-

● Tool

● COOLANT unit

● JIB CRANE

● Both center

● Tool spacer

● Auto transfer system

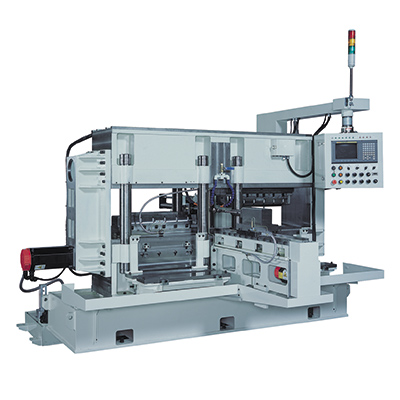

RF-1000

Horizontal Rack Rolling M/C

It processes a SPLINE and a SCREW of shaft outside diameter.

- Features

- 1. The round trip roll can be easily done by 3-axes NC unit.

2. This machine can do 2 places processing by once CHUCK. It is the machine, which is highly precise, high hardness.

3. It is easy to adjust a lining of a tool, and can set processing speed and positioning voluntarily.

4. This eco-friendly machine saves energy and controls noise because it dose not use oil pressure.

5. We realized that processing speed is about 8 seconds of a manual mission shaft (general car) and cycle time is below 30 seconds. - Specifications

-

-

● TYPE RF-1000

● Maximum dia of rolling point φ50

● Maximum width of rolling point 100mm

● Maximum module 1.5

● Maximum TOOL L700*W100

● Stroke 1000mm

● Machine space L2700*W33500*H2200

● Machine weight 7000kg - Special attachments

-

● Rolling to Round trip

● AUTO LOADER