Products

5ton 800st|5ton 600st/800st|5ton 1000st|10ton 1500st|10ton 1300st

5ton 1000st|25ton 1600st|15ton 1600st|5ton 800st|25ton 1800st

Broaching M/C

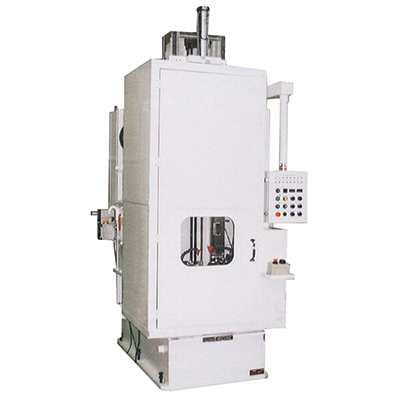

5ton 800st

Table Movement Type Hard Broaching M/C

This machine is made for broach finish processing of heat treated material.

(Using hard broach with special coating, distortion by heat treatment can be finished with high precision and stable processing.)

This table movement machine is able to process at high speed, the velocity is MAX60m/min. It has high efficiency and good workability.

- Features

-

1. Broach finishing of hardness HRC50~62.

(Using hard broach with special coating, heat treatment distortion by heat treatment

can be finished with high precision and stable processing.)

2. High efficiency machining

(High speed machining with cutting speed MAX60m/min)

3. Good workability

(Table movable structure with good workability. Work height from the floor is 1,050mm)

4. There are tremendous merits to energy saving and noise control because this machine doesn’t need hydraulic pump. - Specifications

-

-

● Thrust 50kN

● Stroke 800mm

● Cutting speed 1~60m/min

● Return speed MAX 60m/min

● Height of work mounting 1,050mm

● Number of control axis 2 axis

● Machine size 1,750Wx2,200Lx3,300H

● Machine weight 4,000kg - Special attachments

-

-

● Loading・Unloading stocker

● Front and rear discrimination device

● Work positioning device

● Deburring device

● Chip conveyor

● Pull head・Lift head

● Auto loading device

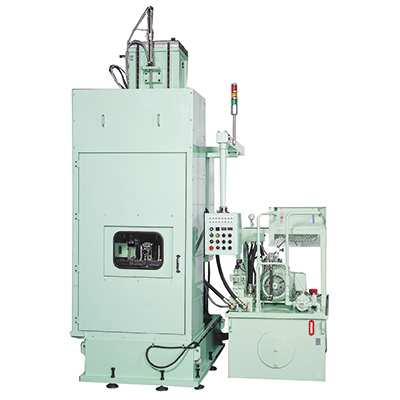

5ton 600st/800st

Tool Movement Hydraulic Broaching M/C

The table is much lower than before by peculiar mechanism.

This is a fully automatic high speed broaching machine that realizes to incorporate in a production line.

- Specifications

-

【5ton600st】

● Type 5ton600st

● Theoretical output 5ton/10MPa

● Hydraulic pump 10MPa/26/min, 4P×5.5kW

● Main cylinder(standard) φ80/600st

● Bottom of work mounting surface 1150GL

● Max. dia.of work φ150

● Machine size 900W×1600L×3200H

● Max.speed(cutting) 1~8m/min

● Return speed 14m/min

● Coolant pump NQJ-400【5ton800st】

● Type 5ton800st

● Theoretical output 5ton/10MPa

● Hydraulic pump 100MPa/36/min, 4P×5.5kW

● Main cylinder(standard) φ80/800st

● Bottom of work mounting surface 1350GL

● Max. dia.of work φ150

● Machine size 900W×1600L×3700H

● Max.speed(cutting) 1~8m/min

● Return speed 14m/min

● Coolant pump NQJ-400 - Special attachments

-

-

● Work counter

● Work feeding device

● Work ejecting device

● Work positioning fixture

● Chip conveyor

● Oil cooler

5ton 1000st

Table Movement Hydraulic Broaching M/C

- Specifications

-

-

● Theoretical output 5ton

● Stroke 1000mm

● Cutting speed 1~7m/min

● Return speed 14m/min

● Main cylinder φ80×1000st

● Hydraulic pump 7.5kW

● Height of work mounting surface FL~1000mm

● Hydraulic tank 160

● Coolant tank 250

● Coolant pump 0.4kW

● Machine size 900W×2000L×3200H

10ton 1500st

Tool Movement Hydraulic Surface Broaching M/C

The machine main body is made compact by peculiar mechanism.

The floor space can be suppressed to the minimum extent.

- Specifications

-

-

● Type Cutter moving type

● Work height 1725mm

● Number of simultaneously machined works 2-process Machining, 1-process A-face machining, 2-process B-face machining

● Cutting speed 3~9m/min

● Return speed 10~14m/min

● Stroke 1500Stroke

● Removal force 10ton(10MPa)

● Hydraulic pump 15kW 4P

● Broaching cylinder φ125×1500ST

● Hydraulic tank capacity 500L

● Coolant tank capacity 500L

● Machine sizes 1150W×1870L×3830mmH - Special attachments

-

-

● Work jig (hydraulic clamp)

● Positioning jig

● With alarm code indication

● Magnet chip conveyor

● Cutter holder

● Oil cooler

10ton 1300st

Table Movement 2-Heads Hydraulic Broaching M/C

- Specifications

-

-

● Theoretical output 10ton

● Stroke 1500mm

● Cutting speed 1~7m/min

● Return speed 14m/min

● Main cylinder φ125×1300st

● Hydraulic pump 22kW

● Height of work mounting surface FL~1000mm

● Hydraulic tank 500

● Coolant tank 350

● Coolant pump 0.75kW

● Machine size 1200W×2000L×3800H

5ton 1000st

Tool Movement Type CNC Broaching M/C

Contributes to the improvement of Production by an excellent cost performance.

- Features

- 1. The speed control is easy because of the NC control.

2. There is a little consumption electric power in comparison with the HYD.PRESSURE type.

*saving energy・no oil temperature rises・low noise

3. This machine is a saving resource because there is no HYD.PRESSURE.Specifications -

-

● Theoretical output 50kN

● Stroke 1,000mm

● Cutting speed 1~10m/min

● Return speed MAX 24m/min

● Work outer diameter MAX 160mm

● Table height 1,500mm

● Machine size 1,900W×2,000L×3,100H

● NC device FANUC 35iB

● Equipment electric power 18.0KVA - Special attachments

-

-

● Work JIG

● PULL HEAD & LIFT HEAD

● With alarm code indication

● Magnet chip conveyor

● Air blow device

25ton 1600st

CNC Table Movement Type Broaching M/C

It realizes highly precise processing by original center of gravity drive.It realizes stable high efficiency processing by arranging a tool in the center of two drive shafts which stood in a row.

- Features

- 1. It realizes highly precise processing by original center of gravity drive. It realizes stable high efficiency processing by arranging a tool in the center of two drive shafts which stood in a row.

2. M/C is provided for various works and tools.

3. Machining speed and stroke can be set optionally.

4. Speedup of return speed (Reduced cycle time)

5. Service tool life becomes long since there is no pulsation of machining speed.

6. There is much merit for energy saving and noise controls, since the hydraulic pump is unnecessary. - Specifications

- ● Theory thrust 250kN

● Cutting speed 1~15m/min

● Return speed 1~15m/min

● Max outer diameter of tool φ95mm

● FANUC 35iB

● Table up-down axis αiS 60/3000 × 2

● Lifter up-down axisαiF 22/3000 × 1

● Table height 1150mm

● M/C size 1900(L)×2600(W)× 5000(H)

● M/C weight 16000kg - Special attachments

-

-

● PULL HEAD (LIFT HEAD)

● Auto transfer unit

● WORK installation FIXTURE

● JIB CRANE

15ton 1600st

CNC Table Movement Type Broaching M/C

The NC unit is adopted for elevating

the lifter and the table.

- Features

- 1. M/C is provided for various works and tools.

2. Machining speed and stroke can be set optionally.

3. Speedup of return speed (Reduced cycle time)

4. Service tool life becomes long

since there is no pulsation of machining speed.

5.There is much merit for energy saving and noise controls

since the hydraulic pump is unnecessary. - Specifications

- ● Thrust 150kN

● Cutting speed 0~20m/min

● Return speed 12~24m/min

● Work mounting height 1,100mm

● Machine size 3,100W×2,400L×4,000H - Special attachments

-

-

● Loading・unloading stockers

● Discrimination system of both sides

● Phase determination device

● Burring machine

● Lift head swing gear

● Pull head・lift head

● Auto loading device

5ton 800st

Compact CNC Helical Broaching M/C

It realizes highly precise processing of internal helical gears.

- Features

- 1. The lead bars are not required and the cost can be reduced with CNC control.

2. Replacement of lead bars and change of gearshift are not required and retooling operation becomes easily.

3. The different specification of helical spline, etc. can be freely processed with CNC control. - Specifications

- ● Theory thrust 50kN

● Cutting speed 1~12m/min

● Return speed 1~12m/min

● Max outer diameter of tool φ30mm

● FANUC 35iB

● Table up-down axis αiF40/3000 × 1

● Broach rotary axis αiF4 /4000 × 1

● Table height 1100mm

● M/C size 2100(L)×1000(W)× 3600(H)

● M/C weight 6000kg - Special attachments

-

-

● PULL HEAD (LIFT HEAD)

● Auto transfer unit

● Work clamp unit

● WORK installation FIXTURE

● Rotary table stocker

25ton 1800st

CNC Helical Broaching M/C

It realizes highly precise processing by original center of gravity drive.

It realizes stable high efficiency processing by arranging a tool in the center of two drive shafts which stood in a row.

- Features

- 1. It realizes highly precise processing by original center of gravity drive.

It realizes stable high efficiency processing by arranging a tool in the center of two drive shafts which stood in a row.

2. This machine is adopted a full closed loop control system by a linear scale (a rotary encoder) for the positioning of a table drive axis and the tool rotary axis.

3. CNC controlling system makes it possible to process freely even if the HELICAL SPLINE’s specifications are different.

4.There are two ways of a spike jig method and the work clamp method about the hold of the work. Either can fit each maker.

5. Cooling system is equipped with to keep a fixed temperature of the cutting oil by the mass production processing. - Specifications

- ● Theory thrust 250kN

● Cutting speed 1~15m/min

● Return speed 1~15m/min

● Max outer diameter of tool φ175mm

● FANUC 35iB

● Table up-down axis αiS60/3000 rpm × 2

● Broach rotary axis αiF40/3000 rpm × 1

● Lifter up-down axis αiF30/3000 rpm × 1

● Loader right & left axis αiF 1 /5000 rpm × 1

● Table height 1550mm

● M/C size 3200(L)×2000(W)× 5500(H)

● M/C weight 20000kg - Special attachments

-

-

● Auto transfer unit

● JIB CRANE

● STOCKER

● CONVEYOR